Industrial sewing machines are an essential tool in the manufacturing and textile industry, playing a crucial role in the production of garments, upholstery, and other fabric-based products.

With their advanced features and efficient performance, these machines have revolutionized the sewing process, increasing productivity and precision.

In this comprehensive guide, we will delve into the world of industrial sewing machines, providing you with all the necessary information to understand their functionality, types, and key considerations when purchasing one.

Whether you are a professional tailor, a small business owner, or simply curious about the mechanics behind these powerful machines, this article will equip you with everything you need to know about industrial sewing machines.

Types of Industrial Sewing Machines

Industrial sewing machines are specialized machines designed to handle heavy-duty sewing tasks in manufacturing and production environments. These machines are built to be durable, reliable, and efficient, allowing businesses to increase their productivity and output.

There are various types of industrial sewing machines available, each with its own unique features and functions.

- Flatbed Sewing Machine

One of the most common types is the flatbed sewing machine, which is widely used in garment factories for sewing flat pieces of fabric together.

- Cylinder Bed Sewing Machine

Another type is the cylinder bed sewing machine, which is ideal for sewing cylindrical or tubular items such as sleeves, cuffs, and collars. The post bed sewing machine, on the other hand, is commonly used for sewing footwear and leather goods, thanks to its raised and vertically positioned sewing bed.

- Overlock Sewing Machine

Additionally, the overlock sewing machine is specifically designed for finishing edges and seams, while the blindstitch sewing machine is perfect for creating invisible hems.

Each type of industrial sewing machine offers specific advantages and is suitable for different applications. By understanding the various types and their capabilities, businesses can better choose the right machine for their specific needs, ensuring optimal results and efficiency in their sewing operations.

Features and Functions of Industrial Sewing Machines

Industrial sewing machines are specifically designed for heavy-duty sewing tasks in commercial settings. These machines are built to withstand continuous use and are capable of handling a wide range of fabrics and materials.

One of the key features of industrial sewing machines is their high sewing speed. They are equipped with powerful motors that allow them to stitch at a much faster rate compared to regular sewing machines. This makes them ideal for large-scale production and can significantly increase productivity in a manufacturing environment.

In addition to speed, industrial sewing machines also come with a variety of stitching options. They can perform straight stitches, zigzag stitches, and even decorative stitches, depending on the model. This versatility allows for greater creative freedom and ensures that different sewing needs can be met.

Another essential feature of industrial sewing machines is their durability. These machines are built to last and can withstand the demands of heavy use. They are constructed with strong and sturdy materials, ensuring that they can handle the rigors of industrial sewing without breaking down.

Additionally, industrial sewing machines often have larger working areas and more robust needle mechanisms, enabling them to handle thicker materials and multiple layers of fabric with ease. Overall, the features of industrial sewing machines enable them to deliver high-quality, efficient, and reliable sewing performance in industrial settings.

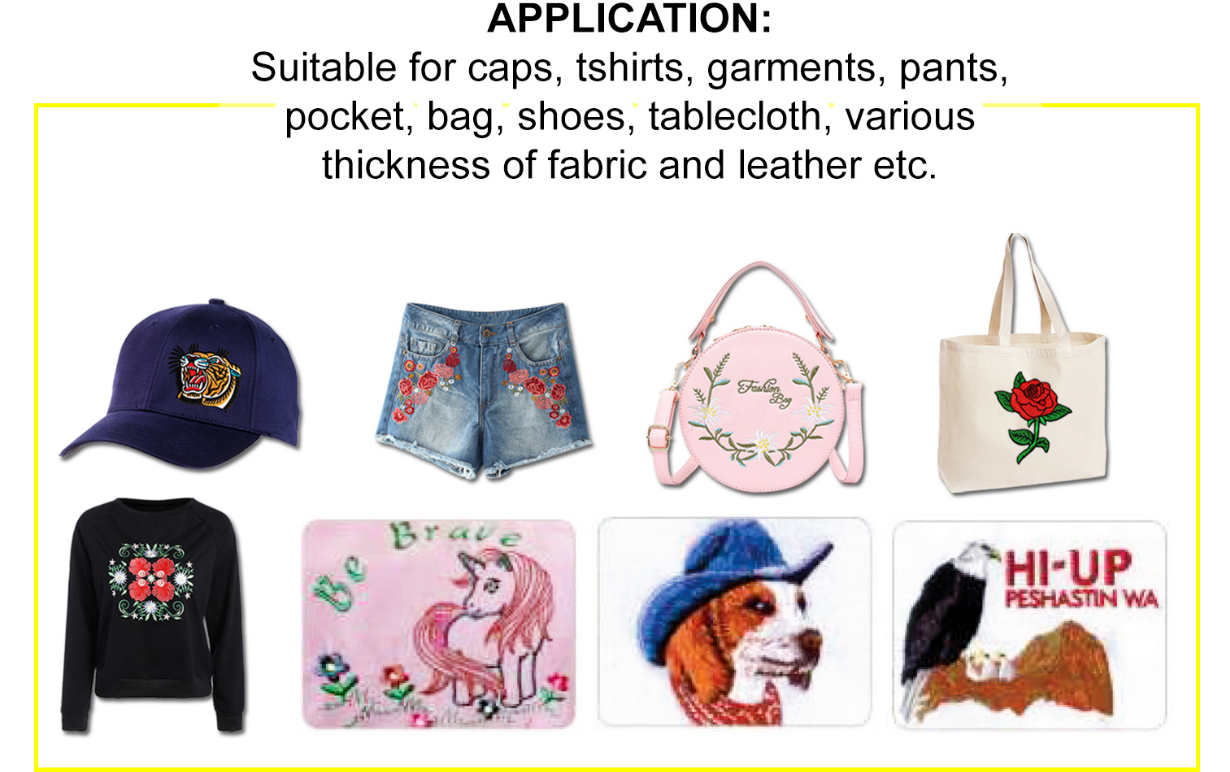

Applications and Industries that Use Industrial Sewing Machines

Industrial sewing machines are widely used across various applications and industries. One of the main industries that rely heavily on industrial sewing machines is the textile industry.

These machines play a crucial role in the production of clothing, upholstery, and other textile products. With their high-speed stitching capabilities and specialized features, industrial sewing machines allow manufacturers to produce garments and fabrics efficiently and with precision.

The automotive industry is another sector that heavily depends on industrial sewing machines. These machines are used to stitch together upholstery for car seats, steering wheels, and other interior components.

The durable and reliable stitches created by industrial sewing machines ensure that the upholstery can withstand the wear and tear of everyday use.

In addition to textiles and automotive, the furniture industry also benefits from the use of industrial sewing machines. These machines are used to sew together upholstery for sofas, chairs, and other furniture pieces.

The precision and strength of the stitches ensure that the upholstery can withstand regular use and maintain its durability over time. Overall, industrial sewing machines are essential tools in applications and industries that require high-quality and efficient stitching.

Choosing the Right Industrial Sewing Machine for Your Needs

When it comes to choosing the right industrial sewing machine for your needs, there are several factors to consider.

First, you'll want to assess the type of work you'll be doing. Different machines are designed for specific tasks, such as sewing heavy-duty fabrics or delicate materials.

Consider the thickness and weight of the fabrics you'll be working with to ensure the machine can handle the job.

Additionally, think about the volume of work you anticipate. If you'll be using the machine for long hours or for large-scale production, you'll want a machine that is durable and can handle high-speed sewing.

Another important factor to consider is the features and functions of the machine. Look for machines that offer a variety of stitches and settings, as well as adjustable settings for tension and speed. These features will allow you to customize your sewing experience and achieve the desired results.

Lastly, don't forget about maintenance and support. Look for machines that are easy to clean and maintain, and consider the availability of spare parts and customer support.

By taking the time to carefully assess your needs and research different machines, you can find the perfect industrial sewing machine that will meet your requirements and help you achieve professional-quality results.

Maintenance and Care Tips for Industrial Sewing Machines

Proper maintenance and care are crucial for keeping industrial sewing machines in optimal condition. Regular maintenance not only extends the lifespan of the machine but also ensures smooth and efficient operation.

To start, it is important to keep the machine clean on a daily basis. This involves removing any dust or debris that may have accumulated during use.

Using a soft brush or a vacuum cleaner, carefully clean the machine, paying close attention to the needle area, feed dogs, and bobbin case.

Additionally, it is essential to oil the machine regularly. This helps to lubricate the moving parts and prevent unnecessary friction. Be sure to use the recommended oil and apply it to the specified areas as outlined in the machine's manual. It is also important to check and replace the needles regularly.

Dull or damaged needles can lead to poor stitching quality and even damage the machine. Lastly, do not forget to check the tension settings. Proper tension ensures balanced stitching and prevents thread breakage.

By following these maintenance and care tips, you can keep your industrial sewing machine running smoothly and efficiently for years to come.

Troubleshooting Common Issues with Industrial Sewing Machines

Troubleshooting common issues with industrial sewing machines is an essential skill for anyone working in the textile industry. These machines are designed to handle heavy-duty sewing tasks, such as sewing thick fabrics or multiple layers of material.

However, they can sometimes encounter problems that may affect their performance. One common issue is thread breakage, which can be caused by various factors, including improper threading, a bent needle, or tension issues.

To troubleshoot this problem, it is important to check the threading path, replace the needle if necessary, and adjust the tension settings.

Another common issue is skipped stitches, which can result in uneven or incomplete stitching. This can be caused by a dull or damaged needle, incorrect needle size for the fabric being sewn, or improper thread tension.

To address this issue, it is important to regularly replace the needle, ensure the correct needle size is being used, and adjust the tension settings accordingly.

Additionally, machine jams are also a common issue that can disrupt the sewing process. This can be caused by tangled or bunched-up thread, a foreign object in the machine, or a misaligned bobbin.

To resolve this issue, it is important to remove any tangled thread or foreign objects, clean the machine regularly, and ensure the bobbin is properly aligned. By troubleshooting these common issues, operators can ensure that industrial sewing machines perform at their best, resulting in high-quality and efficient sewing.

In conclusion, industrial sewing machines play a crucial role in various industries and applications. With a wide range of types and features, these machines are designed to meet different sewing needs.

When choosing the right industrial sewing machine, it is important to consider factors such as the specific requirements of your industry and the desired functions of the machine.

Regular maintenance and proper care are essential for ensuring the longevity and optimal performance of these machines. Additionally, understanding common issues and troubleshooting techniques can help resolve problems efficiently.

By considering these aspects, businesses can make informed decisions and maximize the productivity and efficiency of their industrial sewing machines.

As leading industrial sewing machine suppliers in Malaysia, Tarmah have a wide range of industrial sewing machines available. If you want to know more about Tarmah’s selection of industrial sewing machines, please don't hesitate to contact Tarmah today to discuss your needs. A member of our expertly trained team will eagerly answer any of your questions.